History of Kamianka Ceramics

Origins and Development

Stoneware has a long history that dates back to ancient China. It was Chinese masters who first discovered the method of making ceramics from kaolin clay, which allowed them to create products with exceptional strength. These technologies spread through the Silk Road to Europe, where they were adapted and improved by local craftsmen.

European Renaissance: In medieval Europe, especially in Germany, stoneware pottery gained great importance. It was used to make tableware, in particular beer mugs and jugs, which were noted for their strength and durability. Such products were often decorated with reliefs, coats of arms and other decorative elements, which made them not only functional, but also aesthetically attractive.

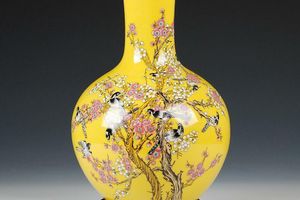

Eastern Tradition: At the same time, in China and Japan, stoneware pottery was used to make dishes that served not only utilitarian, but also ritual purposes. Known for their ability to maintain the temperature of tea, Chinese stoneware teapots have become a symbol of high craftsmanship and aesthetics.

Distribution in the World

In the 18th century, stoneware ceramics gained popularity all over the world due to its unique properties. European manufactories, in particular in England and France, began to mass-produce stone ceramics, which were used both in everyday life and for the manufacture of elite decorative products.

English Stoneware: In England, products made of the so-called "black basalt" ceramics, obtained by adding manganese oxide to clay, became especially popular. This technology made it possible to create deep black products, which were used to make elegant vases, decorative figurines and tableware.

French Stoneware: In France, stoneware ceramics were used for the manufacture of tiles and sanitary ware, which were noted for their high strength and durability. Such products were widely used in the construction of castles and public buildings.

Stoneware Production Technique

Selection and Preparation of Clay

The main material for making ceramic pebbles is clay with a high kaolin content. This clay has excellent plastic properties, which allows craftsmen to create products of complex shape without the risk of their deformation during firing.

Adding additives: In addition to kaolin, quartz and feldspar are added to the clay composition, which improves the mechanical properties of the product and makes it less porous. These additives also help raise the melting point of the clay, which is important for subsequent firing.

Formation

The formation of products from stone mass can be carried out by different methods, depending on the product being created. The most common methods are:

Pottery wheel: This traditional method allows you to create rounded shapes such as plates, cups or vases. The master controls the thickness of the walls and the shape of the product, using various tools to achieve the desired result.

Casting in molds: To create complex parts or mass production, plaster molds are used, into which liquid clay is poured. After hardening, the product is removed from the mold and brought to the desired state by hand.

Drying

After forming, the product remains for drying, which should be slow and uniform. This allows you to avoid cracks and deformations that may occur due to uneven drying of different parts of the product.

Drying time: Drying time can vary from several days to several weeks, depending on the size and thickness of the product. For large products, this process can be quite long, but it is necessary to achieve high quality of the final product.

Burning

Stone ceramics are fired at a very high temperature - from 1200 to 1300 °C. During firing, a significant change in the structure of clay occurs: it becomes hard, impermeable to water and very strong.

Single or Double Firing: In some cases, the pieces are fired twice – first to give them a basic strength, and then to set the glaze, which can be applied after the first firing.

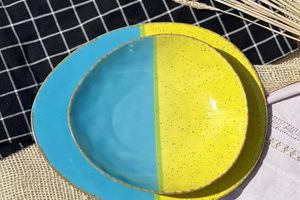

Glazing and Decorating

After the first firing, the product can be covered with a glaze that gives it shine and additional strength. Glaze can be both transparent and colored, depending on aesthetic requirements. Decorative elements, such as ornaments or reliefs, can be applied both before and after glazing.

Glazing technique: Glaze can be applied by dipping the product in liquid, spraying or painting with a brush. After that, the product is fired again, which fixes the glaze and makes it part of the surface of the product.

Modern Use of Stoneware Ceramics

Dishes and Cooking Stuffing

Stoneware ceramics are widely used for the manufacture of dishes, which are characterized by high strength and heat resistance. Such dishes are suitable for daily use, as they withstand high temperatures, do not absorb odors and are easy to clean.

Kitchenware: In addition to plates and cups, stoneware is used to make pots, baking pans, and even teapots that can be used both on the stove and in the oven.

Plumbing and Building Materials

Due to its waterproof properties, stoneware ceramics are ideal for the production of sanitary ware: sinks, toilets, bathtubs and tiles. This material provides durability and resistance to damage, which is especially important for products that are subjected to intensive use.

Tiles for floors and walls: Stone ceramic tiles are widely used in modern construction due to their strength, wear resistance and aesthetic appearance. It is suitable for both internal and external work, ensuring long-term operation.

Decorative Products

Potters also use stoneware to create decorative pieces such as sculptures, vases, fountains, and panels. Thanks to its properties, this material allows you to reproduce the smallest details, which makes it ideal for artistic modeling.

Contemporary art: In contemporary art, stoneware ceramics are used to create both utilitarian and decorative pieces. Masters experiment with shapes, textures and colors, creating unique works that combine traditions and the latest technologies.

Advantages of Kamianka Ceramics

Stone ceramics have a number of advantages that make them popular and in demand in various spheres of life:

Durability: Due to the high firing temperature, products made of stone mass are extremely strong and durable. They are not afraid of mechanical damage and withstand significant loads.

Heat resistance: Stoneware can withstand high temperatures, making it an ideal cookware material that can be used in ovens or on stoves.

Water resistance: After firing, stoneware ceramics becomes impermeable to water, which makes it indispensable for the manufacture of sanitary ware and tiles.

Aesthetic appeal: The smooth surface and the possibility of applying various glazes make stoneware ceramics an excellent choice for decorative products that add a special charm to the interior.

Conclusion

Stone ceramics is not just a material, but an important part of cultural heritage and modern life. It combines strength, durability and aesthetic appeal, which makes it irreplaceable in many areas - from everyday life to art. Its history, which began thousands of years ago, continues today, thanks to masters who preserve traditions and at the same time experiment with new forms and techniques. Stoneware ceramics is a real art that lives and develops together with society.