Porcelain: History, Production and Modern Use

Porcelain is one of the most exquisite and valuable types of ceramics, which impresses with its whiteness, thinness and transparency. It has a centuries-old history and is used both to create elegant tableware and decorative items that have become symbols of luxury and elegance. In this blog we will look at what porcelain is, its history, manufacturing process and modern uses.

What is Porcelain?

Porcelain is a type of ceramic material that is made of thin, white and dense kaolin porcelain. It is characterized by high strength, transparency and aesthetic appeal. The main components of porcelain are kaolin (white clay), feldspar and quartz. Porcelain is fired at high temperatures (from 1200 to 1400 °C), which gives it a characteristic shine and durability.

History of Porcelain

Origin

The origins of porcelain come from China, where it began to be made in the 7th century. Chinese masters improved the technique of porcelain production, which led to the creation of unique products that became highly valued all over the world. Porcelain from China was a luxury item, it was exported to Europe via the Silk Road, where it became a symbol of wealth and high social status.

Tang Dynasty (VII-X centuries): The first examples of porcelain were created during the reign of the Tang Dynasty. They had a characteristic white or light gray color and were extremely thin.

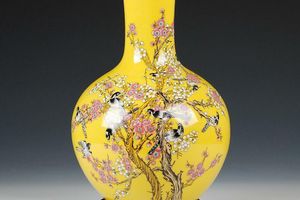

Ming Dynasty (14th–17th centuries): During the Ming Dynasty, porcelain production reached its peak. The products of this period, in particular the blue and white vases and plates, became a symbol of Chinese porcelain and are still among the most desirable collector's items.

Porcelain in Europe

Porcelain from China was so popular in Europe that it was called "white gold". European monarchs and rich citizens wanted to own these products, but the technology of their production remained a secret for a long time. It was only at the beginning of the 18th century that the secret of making porcelain was discovered in Europe.

Meissen Porcelain (Germany): In 1708, the first European porcelain was created in the city of Meissen (Germany). This became possible thanks to the work of the alchemist Johann Friedrich Bettger and the mathematician and physicist Ehrenfried Walter von Chirnhaus. Meissen porcelain quickly gained popularity due to its high quality and unique decorations.

Sèvres Porcelain (France): In the 1740s, the Sèvres manufactory was founded in France and became one of the largest centers of porcelain production in Europe. Sèvres porcelain was noted for its sophisticated design, bright colors and complex reliefs.

Production of porcelain

Preparation of Materials

The main components for making porcelain are kaolin (white clay), quartz and feldspar. Kaolin gives porcelain whiteness and plasticity, quartz adds strength, and feldspar ensures sintering of the mass during firing.

Mixing: All components are mixed in certain proportions, after which the resulting mass is thoroughly mixed and cleaned of impurities to achieve a uniform consistency.

Formation

The formation of porcelain products can be carried out by various methods:

Sculpting on the potter's wheel: This method allows you to create circular products such as plates, cups and vases. The master controls the thickness of the walls and the shape of the product with the help of tools.

Casting in molds: For serial production or creation of complex molds, gypsum molds are used, into which liquid porcelain mass is poured. After hardening, the product is removed from the mold and brought to the desired state by hand.

Drying

After forming, the product is left to dry. Drying should be slow and uniform to avoid cracks and deformations.

Drying time: Drying time depends on the size and thickness of the product and can last from several days to several weeks.

Burning

After drying, the product undergoes the first firing at a temperature of about 900–1000 °C. This ensures its strength and prepares it for the next stages of processing.

Glazing: After the first firing, the product is covered with a glaze that can be transparent or colored. Glaze not only gives porcelain shine, but also increases its strength and water resistance.

Second firing: The glazed product is re-fired at a temperature of 1200 to 1400 °C. This ensures sintering of the glaze and gives porcelain its characteristic shine and hardness.

Modern Use of Porcelain

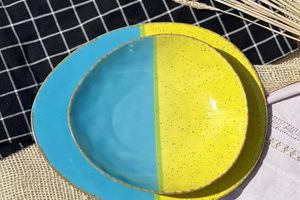

Dishes

Porcelain is widely used for making tableware, including plates, cups, teapots and tableware. Due to its strength, thinness and ability to retain heat, porcelain tableware is ideal for serving both everyday and festive tables.

Elegance and style: Porcelain tableware is often decorated with fine paintings or reliefs, which makes it not only functional, but also a decorative element of the interior.

Decorative Products

Porcelain is used to create decorative items such as figurines, vases, clocks, candlesticks and other interior items. High detailing, the possibility of fine modeling and transparency make porcelain an ideal material for such products.

Collectibles: Decorative porcelain often becomes a collector's item due to its aesthetic value and craftsmanship.

Architectural Elements

In some cases, porcelain is used to create architectural elements, including panels, friezes and facing tiles. It adds elegance and luxury to buildings.

Facade porcelain: In modern architecture, porcelain is sometimes used for facing the facades of buildings, which emphasizes their elegance and creates a unique appearance.

Advantages of porcelain

Porcelain has numerous advantages that make it popular and in demand in various areas of life:

High strength: Porcelain is very strong and durable, which makes it ideal for making tableware and decorative items.

Thinness and transparency: Due to its thinness, porcelain has an elegant and refined appearance. In some cases, it is so transparent that light passes through, which is a sign of high quality material.

Aesthetic appeal: Porcelain products are characterized by exceptional whiteness and shine, which gives them a special aesthetic value.

Conclusion

Porcelain is a true art that combines beauty, strength and durability. Its centuries-old history, sophisticated manufacturing techniques and a wide range of applications make porcelain a unique material that remains a symbol of luxury and elegance to this day. Regardless of whether it is a fine tableware, an exquisite figurine or an architectural element, porcelain always adds a special charm and sophistication to any interior or collection.