Fireclay: What It Is and How It Is Used in Ceramics

Fireclay is a special type of refractory clay that is widely used in ceramic production and construction due to its unique properties. Due to its high firing temperature and ability to withstand heavy loads, fireclay is an important material in the manufacture of ceramic products, which must be particularly strong and heat-resistant. In this blog, we will consider what fireclay is, its properties, manufacturing process and main areas of application.

What is fireclay?

Fireclay is a material made from natural clay that is pre-fired at very high temperatures (around 1500 °C). After firing, the clay is crushed to powder or grains of various sizes and added to other ceramic masses. This process allows you to create a material that has high heat resistance, strength and resistance to mechanical loads.

Fireclay is used as a filler in ceramic masses for the manufacture of products that must withstand extreme temperatures, such as kiln bricks, facing materials, floors in industrial settings, as well as decorative and utilitarian ceramic products.

Properties of fireclay

Fireclay has a number of unique properties that make it an indispensable material in various industries:

1. High Heat Resistance

Fireclay can withstand extremely high temperatures, which makes it ideal for use in conditions where the material is constantly exposed to fire and high temperatures. This property is especially important for the production of refractory bricks and facing materials for furnaces, fireplaces and industrial units.

2. Durability

Due to high density and resistance to mechanical loads, fireclay products have high strength. They can withstand significant physical loads, which makes them reliable even in difficult operating conditions.

3. Resistance to Thermal Fluctuations

Fireclay perfectly withstands sudden changes in temperature, without being subject to cracks or deformations. This makes it ideal for use in conditions where there are frequent and significant temperature fluctuations.

4. Low Porosity

Fireclay has low porosity, which makes it less prone to moisture absorption and exposure to aggressive chemical environments. This property allows you to use fireclay products in difficult industrial conditions and in construction.

Production of fireclay

The process of making fireclay includes several stages:

1. Preliminary firing of clay

The clay is subjected to a primary firing at a very high temperature to turn it into a hard, durable material. Firing takes place in special furnaces where the temperature reaches 1500 °C. At this stage, the clay loses most of its moisture and acquires its main refractory properties.

2. Grinding

After firing, the resulting material is crushed to the required size. Fireclay powder or grains can have different fractions - from fine powder to large grains. The size of the fraction depends on the purposes for which fireclay will be used.

3. Adding to the Ceramic Mass

The resulting fireclay powder or granules are mixed with raw clay or other materials to create a ceramic mass. This mass is then used for the manufacture of various ceramic products, which, after molding, are subjected to re-firing.

Application of Fireclay

Fireclay is widely used in various industries, in particular:

1. Refractory Products

Fireclay is the main material for the production of refractory bricks used in the construction of furnaces, fireplaces, chimneys and industrial furnaces. Due to its high heat resistance, such bricks can withstand extreme temperatures, ensuring the reliable operation of these structures.

2. Building Materials

Fireclay is used in the production of facing tiles and other materials used in the construction of houses and industrial facilities. Such materials have high resistance to wear and temperature fluctuations.

3. Industrial Ceramics

In the industrial sphere, fireclay is used for the manufacture of various parts and elements that work in conditions of high temperatures and aggressive environments. These can be molds for casting metals, crucibles for melting, as well as lining elements of industrial furnaces.

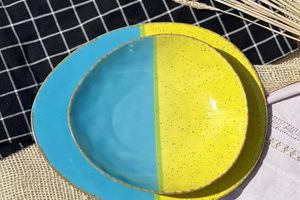

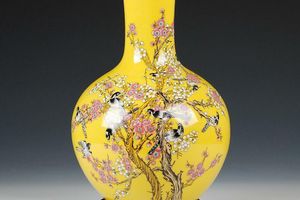

4. Decorative Ceramics

Fireclay is also used in decorative ceramics, especially in the manufacture of sculptures and large works of art that require increased strength and durability. Adding chamotte to clay allows you to create large and complex shapes that do not deform during firing.

Advantages of using Fireclay

Fireclay has numerous advantages that make it a popular material in various industries:

Long service life: Fireclay products are highly durable and can be used for many years without losing their properties.

Environmental friendliness: Fireclay is made from natural materials, which makes it safe for the environment and human health.

The ability to create complex shapes: Thanks to its properties, fireclay allows you to make complex and detailed ceramic products that retain their shape even at high temperatures.

Conclusion

Fireclay is a unique material that combines high heat resistance, strength and durability. It is indispensable in many fields - from construction and industry to decorative arts. Thanks to its properties, fireclay allows you to create products that not only withstand extreme conditions, but also have a high aesthetic value. Wide use of fireclay in ceramics confirms its importance and necessity in the modern world.