Firing Ceramic Ware at Around 1300 Degrees Celsius: Why It Matters and How It Works 🔥

Firing is a critical stage in creating ceramic pieces. It’s a process that determines not only the aesthetic but also the functional qualities of the final product. Although high temperatures can make items brittle at first, it’s important to understand why this is and how it affects the quality of ceramics.

1. Choosing the Firing Temperature

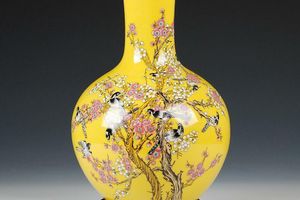

The firing temperature is determined by the type of clay and glaze used. Different types of ceramics, such as porcelain or stoneware, require different temperature ranges. For example, porcelain requires very high temperatures to achieve its translucent and smooth surface, whereas stoneware may be less sensitive to temperature fluctuations. The glaze, which melts at these high temperatures, forms a protective and decorative layer that adds not only aesthetic value but also functionality, making the ware waterproof and resistant to mechanical damage. 🌟

2. Firing Phases: Stages of Transformation

The firing process consists of several critical phases:

-

Dry Firing: Initially, the clay dries and begins to harden but hasn’t yet reached its final strength. This stage is important for removing excess moisture from the piece.

-

Sintering: At high temperatures, clay particles start to fuse, creating a solid and stable material. This is a key stage for achieving the strength required for durable ceramics. 🔥

-

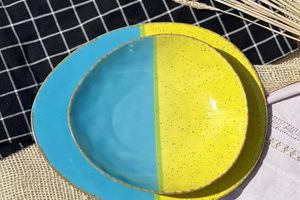

Glazing: If glaze is applied, it melts and bonds to the surface, forming a smooth and shiny layer. This is not only an aesthetic feature but also a practical one, providing waterproofing and protection. 🌈

3. Temperature Control: Why It’s Important

Controlling temperature and the rate of heating/cooling is crucial for achieving high-quality ceramics. Rapid or uncontrolled cooling can lead to cracks or brittleness, negatively affecting the durability of the piece. Therefore, firing at high temperatures requires careful monitoring and precise temperature regulation to ensure optimal results. 🕵️♂️

4. Number of Firing Cycles

Sometimes ceramic pieces go through multiple firing cycles. The first firing, or bisque firing, provides initial strength and prepares the piece for the next stage. The second firing, often with glazing, adds the final layer and enhances the piece’s properties. This process allows for the achievement of the highest quality and durability in the final product. 🔄

5. Clay and Glaze Composition

The composition of clay and glaze also significantly affects the piece's strength and stability. Some compositions can provide greater strength at high temperatures, while others may remain brittle. The correct choice of components and processing techniques, as well as precise adherence to formulations, helps avoid issues and achieve desired results. ⚙️

Conclusion

Although firing at 1300 degrees can make items brittle at the initial stage, controlled processes and proper handling result in ceramics that are not only beautiful but also strong and durable. Firing is an art that transforms simple clay into true masterpieces, captivating with their beauty and functionality. 🌟